Hss Self-Drill Screw Thread Rolling Dies

Introduce:

Every manufacturing industry is constantly looking for innovative tools and technologies to improve operational efficiency and precision. The high-speed steel (HSS) self-drilling thread rolling die is a tool that revolutionizes the threading process. The mold’s combination of durability, speed and accuracy has become a valuable asset to manufacturers across a variety of industries. In this blog, we’ll take an in-depth look at the features, benefits, and applications of high-speed steel self-drilling thread rolling dies.

Features of high-speed steel self-drilling thread rolling die:

HSS self-drill screw thread rolling die is made of high-quality heat-treated alloy steel to ensure its excellent strength and durability. Their ruggedness allows them to withstand high-pressure rolling operations without compromising accuracy or performance. Furthermore, the high-speed steel material allows the mold to maintain its sharpness even when subjected to high temperatures during the rolling process.

PRODUCT DESCRIPTION

Thread rolling die is a conventional die for screw thread machine.It is made of HSS materials with carburizing treatment.It is used for producing thread of screw.

Our thread rolling die covered drywall screw,chipboard screw, self-drill screw,tapping screw,Wooden screw,machine screw,Furniture screw,Electronic screw,Combination screw,Blot,Nuts and other screws.

We can produced the accroding to standard or your screw drawing. And we can R&D accroding to your samples and customer’s request.

We have a strong technical team and used the computer control production process. Take advantage of latest softwares such as CAD/CAM, Solidworks, to perform the advanced technologies by senior engineers, professional heat treatment experts and know-how designers.To ensured the good quality of thread rolling die.

TECHNICAL SPECIFICATION

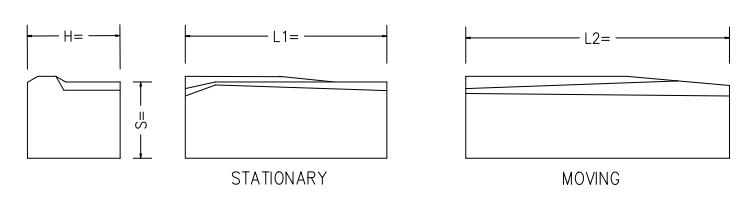

If you order the thread rolling die, please let me know the machine type,moulds size, wire diameter,screw type, teeth type,thread length,point type,outer diameter,inner diameter, and screw drawing .

L1:Stationary dies length

L2:Moving dies length

S: Dies thickness

H: Dies width (Accroding to screws)

| Machine type |

S |

L1 |

L2 |

|

003 |

15 |

45 |

55 |

|

0# |

19 |

51 |

64 |

|

4R |

20 |

60 |

70 |

|

004 |

20 |

65 |

80 |

|

125 |

20 |

70/73 |

82/86 |

|

3/16 |

25 |

75/76 |

89/90 |

|

6R |

25 |

90 |

105 |

|

1/4 |

25 |

100 |

115 |

|

8R |

25 |

108 |

127 |

|

5/16 |

25 |

127 |

140 |

|

3/8 |

25 |

150 |

165 |

MATERIAL

DC53, M2, M42

We will accroding to your products,material,choosing good material and manufacturing technique, and will provide you with the best solution.

DELIVERY TIME

Standard Size:12 Working days

Customization:15 Working days

MOQ

Standard Size: 1 Set.

Customization: 2Sets

PACKING

Packed with antishock material and box, 1 set / box.

SAMPLES

We can offer 1-2Sets as samples to check the size and testing quality, but you should pay the cost and shipping cost.

PAYMENT METHOD

Advance TT, T/T, Western Union, Paypal.

TRANSPORT DETAILS

Shipment by Air, by Train, by Sea, by TNT, DHL,SF-express.

ADVANTAGE

We have over 20 years of professional experience as a manufacturer of thread roling die.

Our price is reasonable and keep best quality for every clients.

We can make Form A, Form E, CO.

Accuracy and efficiency:

HSS self-drill screw thread rolling dies are known for their ability to create clean, precise threads. It achieves this by combining self-drilling functionality, which enables thread formation in one continuous process, and rolling technology, which ensures a consistent thread shape throughout the screw. By eliminating the need for separate drilling and tapping operations, the mold significantly reduces overall manufacturing time, thereby increasing productivity.

Application:

The versatility of HSS self-drill screw thread rolling dies makes them suitable for a variety of applications. It is commonly used in industries such as automotive, aerospace, electronics and construction. In the automotive sector, such molds are indispensable for the production of engine components, transmission assemblies and suspension systems. In the aerospace industry, it is used in the manufacture of airframe components, turbine blades and landing gear. Likewise, in the electronics and construction sectors, the mold plays a vital role in creating precise threads for electrical connections and structural components.

Benefit:

1. Increase productivity: The self-drilling function eliminates the need for separate drilling and tapping operations, thereby reducing production time and increasing productivity.

2. Improved accuracy: High-speed steel material ensures threads are clean and precise, preventing the risk of thread damage or misalignment.

3. Cost-effective: By minimizing material waste and operation time, HSS self-drill screw thread rolling dies provide manufacturers with a cost-effective solution.

4. Long service life: The durable structure of the mold ensures long-term use, minimizing the need for frequent replacement and reducing downtime.

In conclusion:

In summary, HSS self-drill screw thread rolling dies have become an indispensable tool for manufacturers looking to improve the efficiency and precision of their production processes. Its combination of high-speed steel material, durability and self-drilling capabilities revolutionizes thread creation, saving time and cost while delivering superior accuracy. The adoption of this mold across various industries has undoubtedly played a vital role in driving progress and innovation.